The Decline of Steel Production in the UK: A Historical Overview

This article delves into the pivotal changes in the UK steel industry, focusing on the historical significance of steel production, the closure of the last blast furnace at Port Alber, and the transition to electric arc furnaces, all within the context of evolving energy sources and industrial challenges.

Introduction

The steel industry has long been a cornerstone of the UK economy, contributing significantly to industrial growth and job creation. However, a remarkable shift has occurred over the past five decades, with the UK witnessing a dramatic decline in steel production capacity. This article reviews the historical context of steel manufacturing in the UK, the recent shutdown of the last blast furnace at Port Alber, and the implications of transitioning to electric arc furnaces amidst a changing energy landscape.

Historical Context of Steel Production in the UK

Steel production in the UK has undergone significant changes since the 1970s. Once ranked as the fourth-largest producer of steel globally, the UK has experienced a steep decline, now positioned as the 26th biggest producer. This section explores the factors contributing to this decline.

Production Trends Over the Decades

The following points illustrate the shifting landscape of steel production:

- In the 1970s, the UK was a major player in global steel production.

- By the early 2000s, UK production began to decline sharply.

- Technological advancements in other countries outpaced UK production capabilities.

- Deindustrialization trends and economic factors contributed to factory closures.

Comparative Global Production

Historical data shows that countries like China have surged ahead, with their steel production capabilities dwarfing that of the UK. This shift raises questions about the sustainability and competitiveness of UK steel in the global market.

Shutdown of Blast Furnaces

The recent closure of the last blast furnace at Port Alber marks a significant milestone in UK industrial history. This section examines the implications of this closure and the transition to electric arc furnaces.

Understanding Blast Furnace Steel Production

Blast furnaces are traditional methods of producing steel, relying heavily on coal and resulting in high carbon emissions. The process involves:

- Feeding raw materials, including iron ore, coke, and limestone, into the furnace.

- Applying extreme heat to facilitate chemical reactions that convert iron ore into molten iron.

- Pouring the molten iron into molds to create steel products.

The Shift to Electric Arc Furnaces

Electric arc furnaces present a more sustainable alternative, utilizing recycled steel and significantly reducing carbon emissions. The benefits of this method include:

- Lower carbon footprint due to reduced reliance on coal.

- Utilization of scrap steel, promoting recycling and sustainability.

- Greater flexibility in production, allowing for adjustments based on market demand.

Challenges in the Energy Sector

The shift from blast furnaces to electric arc furnaces is not without challenges, particularly concerning energy supply and costs.

Changing Energy Sources in the UK

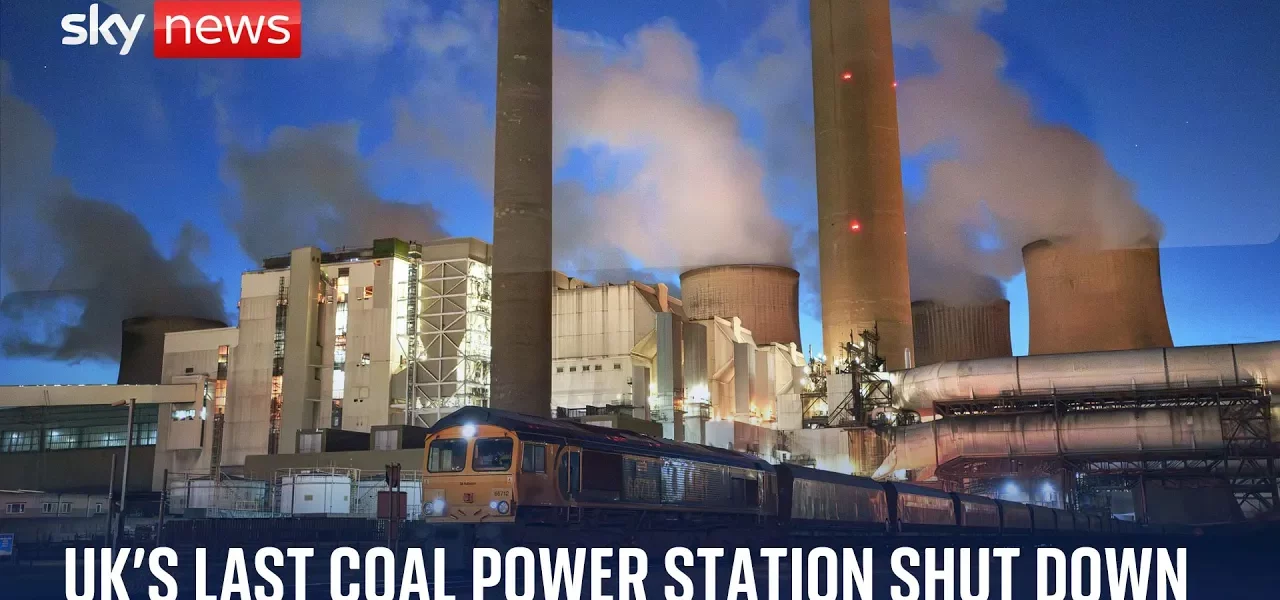

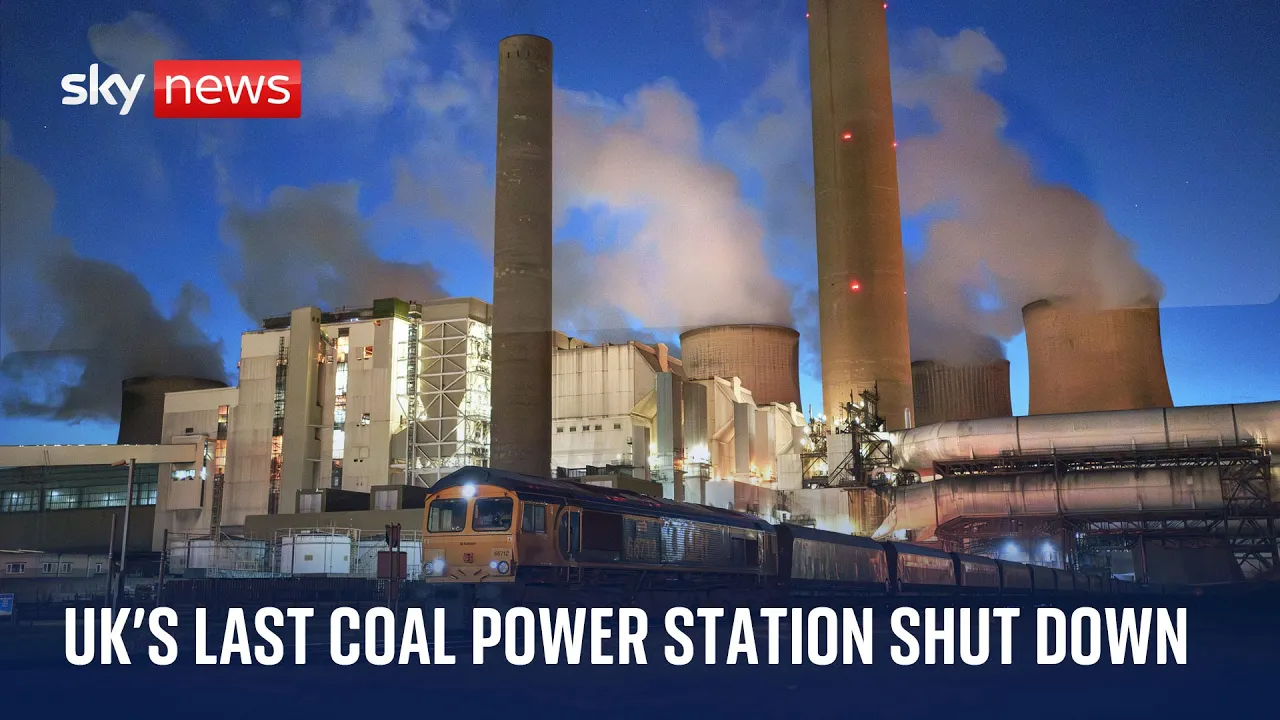

The UK has historically depended on coal for energy production. However, recent trends indicate a significant transition towards renewable sources:

- Coal’s contribution to energy generation has decreased dramatically, culminating in the closure of the last coal-fired power station.

- Renewable energy sources, including wind and solar, are on the rise, with a target for renewables and nuclear to reach 100% of energy consumption.

Impact on Industrial Power Prices

As the UK moves toward renewables, industrial power prices have surged, making it more expensive to produce steel using electric arc furnaces. Key points include:

- The UK currently has the highest industrial power prices among developed nations.

- Rising energy costs pose a significant challenge for manufacturers, potentially hindering the competitiveness of UK steel.

- Investments in renewable infrastructure may take time to yield cost benefits.

Conclusion

The closure of the last blast furnace at Port Alber symbolizes a transformative moment in the UK steel industry. As the country shifts towards electric arc furnaces and renewable energy sources, it faces both opportunities and challenges. The decline in steel production highlights the need for adaptation and innovation within the industry. Stakeholders must navigate the complexities of energy costs, sustainability, and market competitiveness to ensure a viable future for UK steel production.

For further insights into the steel industry and energy transitions, explore our related articles on UK Steel History and Renewable Energy Solutions.

“`